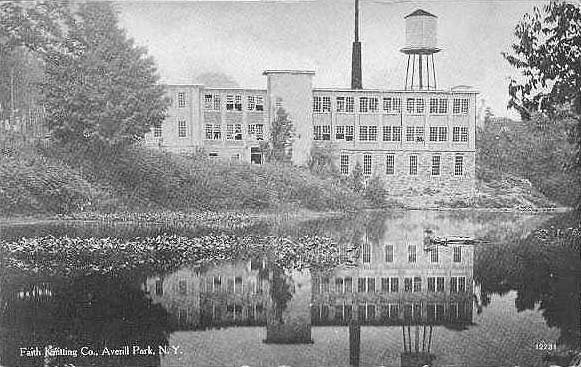

My Memories of the

Operation of Faith Mills,

Averill Park, New York

By Elwin Richard (Dick) Castle

If you were to go to the mill at the bottom of the hill on Burden Lake Road, you will notice a warehouse on

the right side of the road going down the hill. This is where it all began.

Trucks would bring in bales and bags of cotton materials and some mixed blends of different types of cloth materials.

It would be stored in that warehouse until needed.

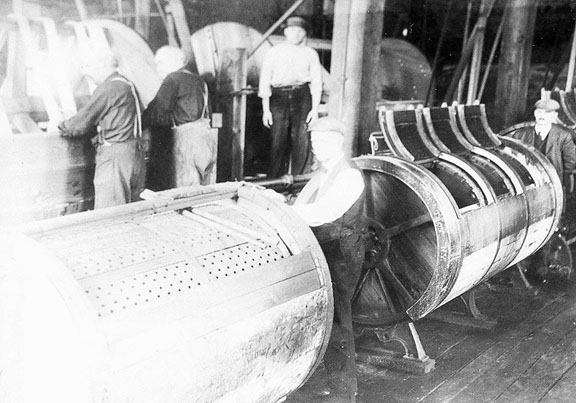

When needed, mill trucks would bring a few bales at a time over to the building across the road that was referred

to as the lower mill. There the bales would be opened in the picking room. The materials would be put into what

they called hoppers. It looked like what a small dumpster looks like today. This machine was called the picker.

The machine operator would fill the hoppers with the cotton and mixed blends of material and it would go through

the machine and hundreds of needlelike hooks on a huge belt would pick it apart and it would come out the other

end blended and picked apart into cotton. It would then go to the Garnet Room in the cellar of the lower mill and

also be put into hoppers. The material would go through the garnet machine and would come out fluffed like cotton

candy.

The cotton would then be sent through the pipe line that was connected from the lower mill to the upper mill.

It was blown up through that pipe to the cardroom bins. (Parts of the pipe are still lying on the ground between

the mills.) On occasions as you went down the road you would see cotton blowing in the air as the pipe at times

would spring a leak. (The snakes, frogs and turtles just loved it as it made a good nesting place along the banks

for them.) The cotton was blown into small bins about 6 feet wide and 10 feet high. The bins were behind the card

machines in what was called the cardroom The machine operator would have to go in the bins as the cotton was being

blown in and stamp it down as it was blowing all over him. As the cotton pile got higher, he had to make sure he

kept a hole down to the door to exit. He would be covered from head to toe with cotton as it got very hot in the

bin and the cotton would stick to you.

The cardroom was what is now the Signature Stone room, (the back room of the ground floor.). The machine operator

would then take arms full of the cotton and fill hoppers connected to the card machine. The material would go through

the machines on large belts and come out the other end as yarn approximately 30 ends that would go onto a roller

about 5 feet long.

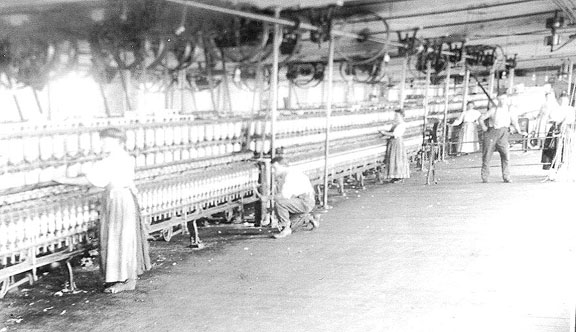

The rolls would then be put in carts and go from the first floor (ground level) to the second floor known as

the spinning room (center of this page) or sometimes called the winding room. The rolls would be put on the back

of the machine called jacks or sometimes called mule spinners. The approximately 30 ends would be put into the

jacks and each end would go through wax rings that would hold the yarn together. The operator would be on the other

side and the yarn would be attached to a part of the machine and the machine would stretch it out (I'm guessing

5 feet) and as the machine moved back in the 30 lines of yarn would wrap around bobbins, eventually filling the

bobbins, and the operator would have to break the yarn, throw the full bobbins into carts and begin another 30

lines changing the big rolls in the back when needed. The operator would walk behind the machine as it went back

and forth winding the yarn and would connect any strands that might break. The carts of bobbins would then go to

the front part of the second floor to the knitting machines. The knitting machines would knit in a circle and would

come out the bottom of the knitting machine. The operator would have to cut the material and remove it and then

start another pile. The material would be stacked and put into carts and taken to the cellar, which was the washroom.

There the material would be washed and dried in big machines and in some cases sent to the next room to be dyed.

Some material was dyed depending on the color of the underwear being made. The material was also turned inside

out on many occasions by the machines to dry.

At times you could tell what color garments were being dyed by the color of the water in the pond. The creek

ran to the mouth of the first Burden Lake. Many times being young, we would swim in the creek just below the lower

mill and then suddenly we would have to leave as the color of the water would change. Many people would fish and

hunt frogs in the pond and if you were lucky enough to catch a turtle, you could take it to Aaron Dibble and he

would make turtle soup and if you wanted the shell he would paint it and give it back to you.

Cutting room, September 1, 1954, staffed by (l-r) Clayton Barnum, Charles Dawson, Fred "Snick"

Shoemaker, Leslie French, George Gallagher

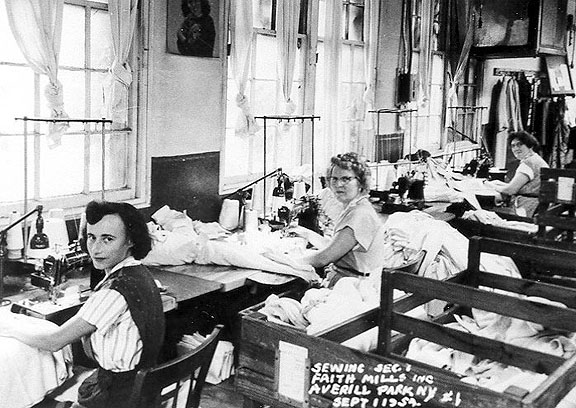

Once the material was washed and dried it would be put on the elevator and sent up one floor to the cutting

room, which was on the upper cellar floor. There it was placed on the tables and it would be cut into different

parts of the underwear: legs, cuffs, drawer's panels, cuffs, collars and body of the shirts. The pieces would be

tied in bundles of, I believe, 36 units per bundle and sent up one floor to the sewing room or sometimes called

the finishing room which was in the front of the building at ground level. There it would be passed out to the

sewing machine operators and the body of the underwear would be assembled. It would be tied back up and put in

carts to go to the machines to sew the cuffs on the legs and sleeves and collars. Then on the same floor to the

sewing machines that sewed the elastic on the waist of the underwear, then onto the buttonhole department on the

same floor for buttons, then the size labels and brand name would be sewed on. (Maybe not in that order.)

Sewing room, September 1, 1954, staffed by (l-r) Ida Zipkin, Jennie Cann, Florence Shaw

There were tags with stickers on them for each department and the operators would take their sticker off the

card. They would get paid by the amount of stickers they had.

Now the underwear was all put together. I can remember Lucien O'Keefe and later William Lance coming through

the mill with a box in front of them and a strap around their necks with the pay envelopes for all the employees.

Each sewing machine operator and inspectors were paid by piece work. Next it would be sent to the inspectors (approximately

5 or 6 in the corridor overlooking the dock area on the same floor and they would clip the extra threads that were

hanging on from the sewers and would put their tag in the bundle that showed the dozen was inspected. Then they

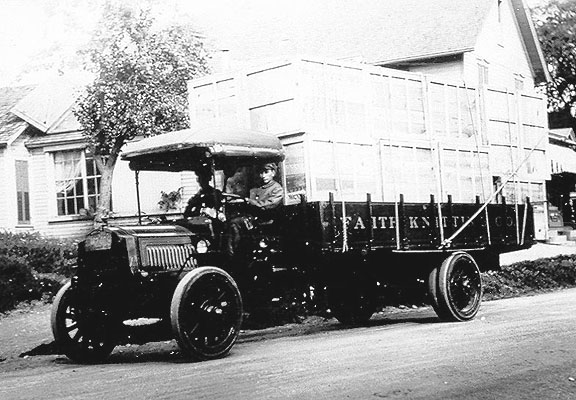

were put back in carts to go back down one floor to be folded, pressed and put into boxes. Then it was sent by

mill truck up the hill to the shipping department under the main office building where it was stored and packed

to be shipped. Sometimes it was shipped out from the first cellar in the front of the building where they were

folded and packed.

To understand the floors of the mill I will explain it this way. The front of the mill was two stories high.

The back was four stories. Two cellar floors and then the first and second floors above ground.

Many of the homes around the mill were owned and maintained by the mill and if you worked there you could rent

the home. I heard something like $4.50 per month which was taken out of your pay each week like $1.10 per week

in the 30s and 40s; a little more in the 50s and 60s. We lived at 1508 Burden Lake Road and $25.00 per month sounds

familiar. Across the street of the upper mill on the hill was a boarding house that was owned and operated by the

mill. Many people from the Capital District that worked in the mill would board there and then they would go home

on weekends. In my time the boarding house was run by the mother and father of Pittsburgh Pirates pitcher Elroy

Leon Face. The Faces were great, loving, caring people and the rooms were filled almost all the time. I can still

remember supper time and everyone coming down for supper at the huge dining room table back in the 40s. And Boy!

Could Mrs. Face cook!

There was a night club under the main office but I don't remember that too well, but I do remember the fellow

that ran the friendly tavern in Crooked Lake. His name was Carl Norman, and he used to come with his sound truck

and show movies to us kids and eventually doing the same at the Crystal Lake dance hall in the 40s. The nightclub

was to entertain the workers in their spare time. I heard about dances and the whole bit.

On breaks for lunch, the men had a horseshoe pit in the back of the mill outside the wash room and many games

of horseshoes were played there.

I can remember the Mill's owner William D. Mahony, who lived in the mansion at the top of the hill, as a very

caring individual who always wore a hat. A very distinguished gentleman, he had a chauffeur whose name was Jerry.

All the kids just loved Jerry as he gave us candy and always kidded around with us.

William Mahony, above, with Peter McCarthy founded Faith Knitting Company in 1897. He was president

of the company and also president of the Board of Education and instrumental in forming the Averill Park Central

School District.

I remember Mr. Arthur Butler, who I believe was vice-president of the Mill until Mr. Mahony passed away and

then became president. A quiet man who lived on Orient Avenue. A man that cared about his employees and would help

in any way if you had asked. My Dad and I also worked for Mr. and Mrs. Butler at their home doing odd jobs. They

were both special people.

If you had worked in the Mill chances are that your mother, father, sister, brother, aunt, uncle, nephew, niece,

grandmother, grandfather or cousin all worked there at one time or still worked there with you. Nearly every member

of my family worked in the Mill. My Dad fired the boiler there for nearly 40 years. I can still hear the steam

whistle blow at noon and at 6:00 p.m. Living nearby, I remember washing my car and then my Dad would be stoking

the boiler and the black soot would start falling and my car would be all black specks. Needless to say I wasn't

a happy camper, and the people that just hung their laundry out to dry weren't, either!

Below: Faith Mills picnic at Glass Lake, 1954.

People that worked in the Mill were all great people. As I said a lot of them were related and were all there

doing the same thing - working to raise their families and just trying to make a living.

My dad, Leroy K. Castle, Sr., also called "Gip" or "Pop," would have to make his rounds

through the Mill and then go to the lower mill. There were different keys throughout the Mill where he would go

and would have a clock strapped on his shoulder, and I believe about every three hours he would punch his clock

with a key located at different stations throughout the upper and lower mills to show that he checked each section

for fire, intruders, etc. We would play in the Mill and knew about when he was going to come around and we would

hide until he went by. We were very careful not to touch the machines or do any harm to anything, as we knew the

importance of things staying the way they were left, (except for a few wax rings around Halloween).

The boiler was fired by hard coal. The mill trucks would go to Troy to the train yards off First Street and

would get loads of coal that came in by train and would dump them in the coal bin, which was located just outside

the door that now is the entrance to Signature Stones. There was a small alleyway about 6 feet wide and about 20

feet long between the entrance and the coal bin. As the trucks pulled in the Mill, they would come in the driveway

and would first pass the turbine room on the right, then the steam room, then by the boiler room in the cellar

on the right and the smoke stack on the left and then to the coal bin on the right. This part of the Mill has been

torn down, but, looking at the entrance to Signature Stones, about 6 feet out is where these rooms were located.

The 20-foot alleyway led to the boiler room.

If you drive past the entrance to Signature Stones today you can see the stances for the water tower and next

to that was the garage for the Mill trucks on the left. On the right is a work shed; down over the hill you can

still see the pump house that pumped water to the Mill from the creek behind the Mill. At one time there were a

couple of machines that were run by water power, I believe the washing machines.

Many people fished that creek and caught some great bullheads, walleyes, pickerel, bass and all kinds of fish.

Once in a while they would lower the water level, and I remember catching some big fish by hand.

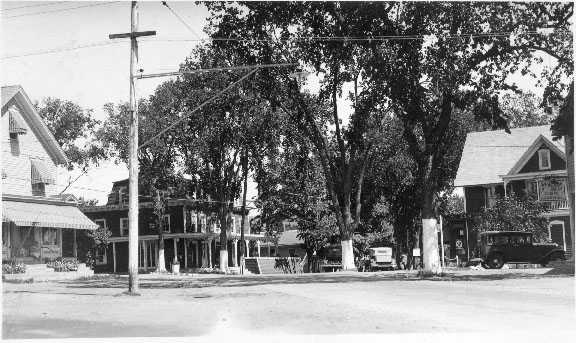

Mill housing along Burden Lake Road

After the trolleys stopped, many people who didn't live in the community would take the United Traction bus

(now CDTA) out from Troy. It ran nearly every hour on the hour as many people rode it to Crystal Lake and Glass

Lake to swim and to the Dance Hall and Merry-go-round at Crystal Lake. I believe that last bus out was 11:00 p.m.

The bus turned around at Gifford's Market in Glass Lake. The United Traction Company paid to have the merry-go-round

moved from Rensselaer to Crystal Lake to draw more people to take buses to the Crystal Lake area. The bus service

was discontinued also maybe in the 60s.

I worked in the Mill in 1957 and believe my starting pay was around $1.59 per hour. I worked in nearly all departments,

wherever I was needed, for about 5 years.

Most people that worked in the Mill shopped locally in the village at Eastman's Variety

Store on the corner of Burden Lake Road and (now) Route 43; behind Eastman's was the Grand Union store. On

the opposite corner was Bunger's store, which became Zane's Market; then Barnum's News Room (great penny candy);

then the A&P. Across from that was the Lakeview Hotel and bowling alley.

Averill Park's main street in the 1930s

Then Silberg's Park Pharmacy ... and the post office on the corner of Route 43 and Orient Avenue next to the Pharmacy.

Other businesses were Harry O'Donnell's Liquor Store, Henry Karl's taxi, Larkin's Funeral Home on Crystal Lake

Road; Dreis's Hardware (where Legenbauer Gas & Oil is today); Garstang's Garage, Marty Butler's Service Station,

Craver's Barber Shop behind Bunger's and Bruno's Barber Shop behind the Variety Store, Heffner's Bar next to Legenbauer's.

Back in the Mill days, the village of Averill Park thrived well.

I can remember Joe Warren would sell life insurance at the Mill. He would come once a week and collect I believe

25 cents a week back in the 1940s & 1950s. He would walk through the Mill to each customer and collect.

At one time during the War, the Mill made wool underwear and overcoat material for the U.S. government. The

long underwear had button panels that opened in the back. I wore them on a few occasions and remember, Boy, how

they would itch!!

Many knitting machines were placed under the main office on the hill for their government contracts and much

of the overcoat material was made there.

Back in those days there were armed guards at each entrance to the Mill while they had government contracts.

The bulk of this product was Thermal Knit, a soft comfortable material that came in all colors: white, pink, red,

black and I believe others that I forgot.

My young days of growing up around the Faith Mills holds a special place in my heart. My Dad had to work hard

to raise his family on little money, but I was able to be with him when he was home and also spent a lot of time

with him when he worked. The Mill produced warm clothing and warm, friendly people. I will never forget my experience

of growing up in and around Faith Mills - an experience I will take with me when I go.

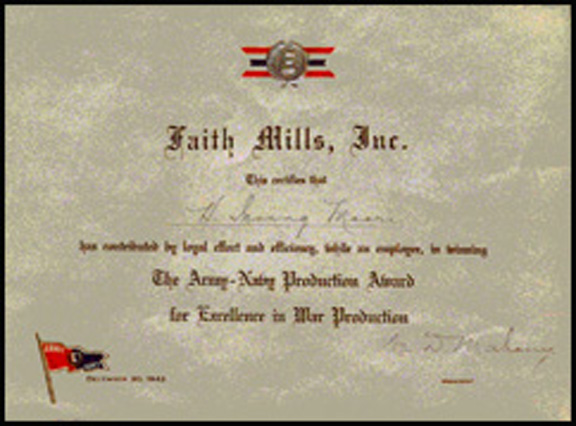

H. Irving Moore and the other Faith Mills employees were each given an Army-Navy Production

Award certificate along with an E Award pin in recognition of their part in the war effort.

The Mill formed a union and was there for a long time. When textile work began moving South, the union workers

voted to go on strike. The meeting was held at the Sgt. Walter Adams Post. The Mill owners said that if the workers

went on strike they would close the Mill. The workers didn't believe that and voted to strike.

I can still see the sign on the door. It said this Mill will be closed as of I believe maybe July. A sad, sad,

day for Averill Park. Little by little, the machines were shipped out and the Mill closed. My Dad worked for about

another 6 months to a year and then Faith Knitting Mills was gone, I believe July 1962. Shortly after that, a company

from Seneca Falls, operated part of the Mill, then they closed and sold the Mill to the Lally Knitting Mills owned

by Mr. Kenneth Lally, who was a well-known contributor to RPI. Mr. Lally operated part of it for a short time,

and then I believe it was sold to Ebel Box Company and then to someone who sold auto parts and now Signature Stones.

Labels for Faith Mills ribbed shirts and drawers: "Perfect Fitting; Spring Needle"

|